NEWS

AmCham News tags

- Accounting / Financial

- AmCham Norway

- Company Profiles

- Education / Research

- Entertainment

- Food & Beverage

- Government

- Healthcare

- Hotel/ Restaurants/ Conferences

- Insurance

- International Leadership Interview Series

- Membership Guide

- Publications

- Rising Leaders

- Technology

- Trade

- Travel

Business News tags

- Accounting / Financial

- Airline / Travel

- Automobile / Transport

- Chemicals / Metals

- Communications/PR/Media

- Culture / Lifestyle

- Defense / Security

- Education / Research

- Energy

- Entertainment & Lifestyle

- Financial / Investment

- Food & Beverage

- Government

- Health

- Human Resources

- Insurance

- IP & Innovation

- Legal

- Management Consulting

- Manufacturing

- Pharmaceutical

- Politics

- Property / Real Estate

- Seafood

- Shipping & Offshore

- Statistics

- Tax

- Technology

- Trade

AmCham Member Company Profile: Air Products Norway – Climate Cleaning Technology

Category: AmCham Norway

Pioneering nitrogen membrane technology worldwide, Kristiansand-based Air Products was the world’s first company to commercialize nitrogen separation on board ships and offshore installations.

Developing the existing technology, they are now piloting carbon dioxide capturing, as their installations — that enable CO2 separation from coal-fired power plants and the cement industry —literally purify the air.

Air Products Norway was established in 1970 and in 1984 they launched the world’s first equipment designed to separate nitrogen. They have since developed more than 1,500 marine systems and recently won a contract to supply a membrane nitrogen generator unit to the Shell Prelude FLNG – the world’s largest floating liquefied gas platform.

“We are proud to have been selected as a key supplier to this amazing project, and this confirms our position as leading membrane technology to the marine, oil & gas market worldwide,” Managing Director Tom Cantero says.

“We are the leading player within nitrogen generators on ships. Our solutions ensure that ships fulfil their emission obligations. In fact, we’ve experienced that ships that have previously chosen other suppliers have approached us to replace the entire facility, as we adapt our solutions to match developments.”

Repurposing

Capitalizing on the capturing of oxygen, nitrogen and hydrogen, Air Products — whose headquarters is in Allentown, Pennsylvania — is able to recycle the products, providing sustainable solutions in other fields.

“It is actually rather fantastic that we are able to recycle both oxygen and hydrogen, using the same approach and technique as when we work with nitrogen.”

“We provide hydrogen for cars in the US, nitrogen is used by Yara in their Mila fertilizer and we provide oxygen to passengers on the most highly-elevated railway in the world in Tibet,” he explains.

Carbon Dioxide Separation

Having exceeded $10 billion in sales globally in 2016, the world’s fourth largest industrial gas company operates in over 50 countries, but the gas separation technique and membranes were invented in Kristiansand, Norway, where they are still produced today.

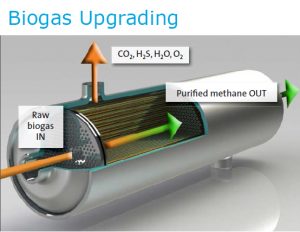

Through further research, and in collaboration with the Norwegian university NTNU, Air Products has designed and fabricated a uniquely coated membrane, optimized for commercial CO2 transport— potentially revolutionizing emission challenges in the process, recycling, power station, shipping and offshore industries.

“In light of the Paris Agreement, and that global energy demand and CO2 emissions will increase correspondingly with the growing population, CO2 capture solutions can play a major role in the efforts towards greener industries.”

“Having tested the technology for more than one year at Norcem cement plant in Breivik, Norway, we are close to our goal of capturing 80% or the CO2, with 95% purity.”

“The membrane technology is very energy efficient, and with no solvents, chemicals or moving parts, it is both reliable and cost-effective. The aim is to have the prototype ready for 2020,” Cantero says.

Air Products is a Fortune 500 company and has been a valued AmCham member since 2006.

Source: AmCham